Dart Impact Tester – HMI stands as a premium testing instrument widely utilized across diverse packaging industries for evaluating the resilience of plastic films against various applied forces. The device features an electromagnetic dart hold/release mechanism, ensuring uninterrupted force application. Capable of securely holding weights up to 2 kg, this mechanism adds to the instrument’s reliability. The user-friendly HMI display facilitates the easy determination of the number of falls executed in a single test.

Simplified sample handling is achieved through a foot switch, allowing convenient clamping or unclamping. The machine is equipped with pneumatic clamping, ensuring the wrinkle-free fixation of the test specimen. To prevent dart rebound upon impact, a shielding device is incorporated into the machine, enhancing safety and precision in testing.

| Parameter | Specification |

|---|---|

| Type of Test | Free Falling Dart Impact Test |

| Release Mechanism | Electromagnetic dart hold/release via paddle switch |

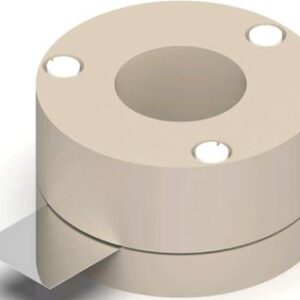

| Clamping Unit | Circular annular clamping unit with zero slippage |

| Material Construction | Mild Steel (Powder Coated) / Sturdy Aluminum Structure |

| Inner Diameter of Clamp | 127 mm |

| Dart Head Diameter | Method A: 38 mm Method B: 50.8 mm ± 0.13 mm |

| Maximum Dart Drop Height | Method A: 660 mm Method B: 1524 mm |

| Dart Dimensions (Diameter × Length) | Method A: 38 mm ± 1 mm × 212.8 mm Method B: 50 mm ± 1 mm × 226.5 mm |

| Dart Head Material | Method A: Phenolic Method B: Stainless Steel |

| Max Dart Holding Capacity | 2 kg |

| Height Adjustment Scale (Least Count) | 1 mm |

| Clamping Pressure (Pneumatic) | 3–4 Bar (pneumatic supply in customer’s scope) |

| Control Panel | Digital Counter (In-built in HMI) |

| Power Supply | 220V AC, 50 Hz, Single Phase |

support & logistics

and reliable delivery

100% Secure

We are a young and dynamic company led by a group of seasoned professionals with years of experience in the supply, installation, and training of scientific and laboratory equipment.

Developed @seogrey

Copyright © 2025. Shivas Scientific Supplies FZE