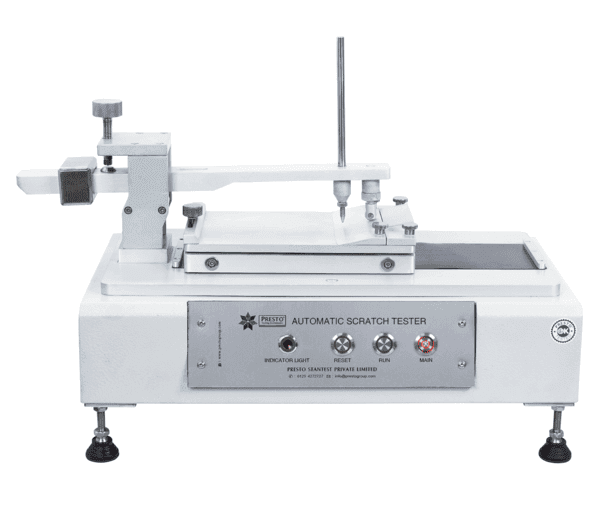

Scratch Hardness Tester Motorized is a unique test instrument to determine the resistance to scratch under a specified load. Tests are conducted either on a go/no go basic by testing at a single specified load on the diamond stylus tip or by increasing loads to determine the minimum load at which the coating is Penetrated. PRESTO Scratch Hardness Tester is designed as per standard ISO 1518-1

Specifications

- Motorized oscillating arm with Teflon rollers for noise free movement Ergonomic design with Electronic controls

- Highly accurate test results under uniform load and specified diameter. Equipped with Hardened steel hemispherical tipFully Automatic testing through motorized system

- Uniform load by weights on Stylus tip for evenness in testing

- Firm holding of Test sample by Clamping device

- A lowering device with a flat ramp brings the stylus smoothly into contact with the coating at the Beginning of the movement of the panel holder

- Instant braking system

- Light Indicator for sample failure notification with visual alarm

Technical Specifications

| Parameter | Specification |

|---|---|

| Sample Size | 200 × 100 mm |

| Scratching Mechanism | Motorized |

| Lowering Ramp Angle | 12.5° ± 2.5° |

| Load on Stylus | 0.5N ×1, 1N ×1, 2N ×2, 5N ×1, 10N ×1 |

| Motor Power | 15 W |

| Stylus Travel Length | 120 mm |

| Stylus Moving Speed | 35 ± 5 mm/s |

| Sample Thickness Compatibility | 0.7 to 1 mm |

| Stylus Tip Diameter | 1 mm ± 0.01 mm (Hemispherical) |

| Stylus Tip Material | Hardened Steel |

Construction & Highlights

| Feature | Details |

|---|---|

| Material | Aluminum (Machining) + Mild Steel (Outer Body) |

| Finish | Powder-coated Havel Gray & Blue combination with chrome/zinc plating |

| Corrosion Resistance | Yes – Chrome/Zinc plating for durability |

| Hardened Steel Tip | Included |

| Overall Dimensions | 483 × 270 × 370 mm |